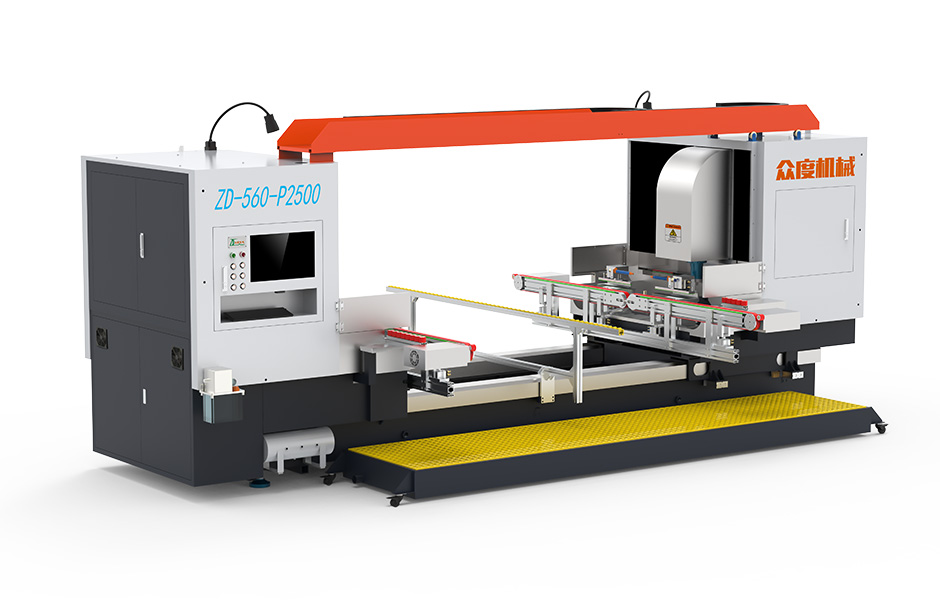

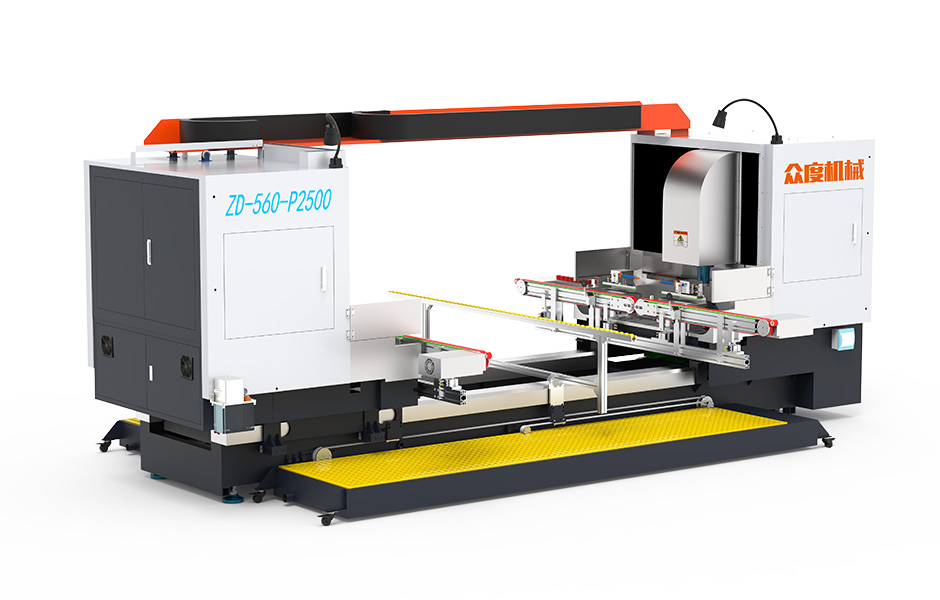

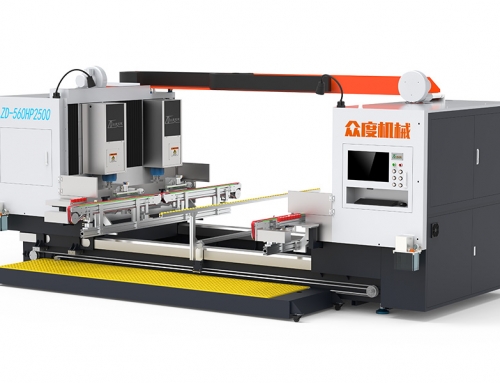

Project Description

Zhongdu bilateral connection intelligent chamfering machine, the equipment completes the entire processing process in a pipeline mode, without manual handling, using automatic image capture positioning glass chamfering smooth, efficient, accurate and other advantages, saving time and labor.

| Equipment name | Double-sided dual-spindle chamfering machine |

|---|---|

| Equipment brand | Zhongdu |

| Equipment origin | Guangdong Dongguan |

| Equipment model | ZD-560-P2500 |

| Minimum processed glass size | 230mm*560mm |

| Maximum processing glass size | 1500mm*25000mm |

| Chamfering range | R3-R45mm/C3-C30mm |

| Processing glass thickness | 3mm-10mm |

| Chamfering speed | 2-3 pieces/minute |

| Chamfering accuracy | ±0.05mm |

| Device power consumption | About 17kVA |

| Device size | 4.9m*2.7m*2.1m |

| Device weight | About 4000kg |

| Operating system | Zhongdu OS |

| Machine use | Applied to all glass products that require chamfering, such as bathroom glass, furniture countertop glass, architectural glass, etc. (large and thick glass have more obvious advantages) |

- With automatic opening and closing function to achieve intelligent chamfering

- Using automatic compensation positioning technology to ensure absolute standard chamfering, smooth interface, tolerance within ±0.03mm

- Chamfer rough grinding, fine grinding, polishing once in place

- Process before and after docking to realize automatic information docking

- The quality of the processing port is stable and the scrap rate is low

- For glass products, customize the intelligent chamfering line that is best for you

N/A

- The machine bed is made of 12MM thick-walled steel pipe after welding and heat treatment to ensure stable structure

- The X, Y and Z axes all use TBI grinding grade precision ball screw, high precision rectangular linear guide rail to ensure the stability and precision of the machine tool operation

- Professional control system, international standard G code instruction

- Multi-wheel coaxial design, no need to change wheels, greatly reducing processing time

N/A